Our Quality Assurance and Quality Control Management has developed QA/QC procedures and standard operating procedures (SOPs) in accordance with ASME, ANSI/AWS, USP, CFR, FDA, AWWA, SEMI, OSHPD, NFPH 99, 99c and 13 UBC, UPC, UMC for plumbing, piping, mechanical, process ultra high purity piping systems, along with standard material specifications and installation specifications.

|

Compliance with the following: |

Certifiers: |

||

|

|

|

|

|

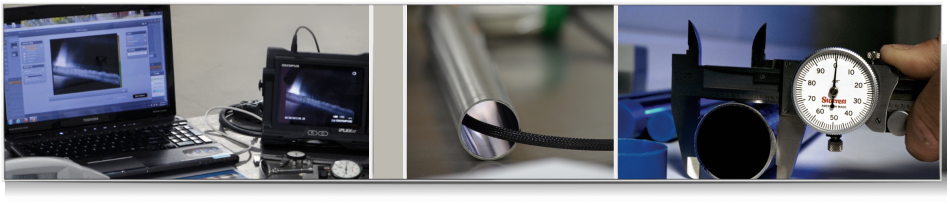

In-house inspection equipment:

|

Trained in and certified as:

|

||

|

Other Training:

|

We provide standard operating procedures (SOPs), commissioning,

|

||

|

ASME/NBIC Code Stamps:

|

|||

Our well-equipped pipe fabrication facility ensures that critical project installation schedules are fulfilled. Shop/field welders are certified to ASME/AWS Code criteria and updated as industry standards dictate. Our 50 qualified welding procedures include but are not limited to Hastelloy, Duplex, Chromes, AL6XN and other steel combinations.

To meet the client’s stringent specifications, our Quality Programs are managed by a licensed professional engineer and further staffed by ASNT Level II and AWS CWI. Our project specific quality plans meet or exceed the client’s specification and ensures materials, fabrications, installations and final testing meet the specification and governing code requirements. These QC Plans are in addition to our approved Quality Programs.

Murray extends an invitation to visit our corporate office and tour our fabrication facility, including our Class 10 cleanroom for Biopharmaceutical and Semiconductor fabrications.